I-Zinc Alloy Die Casting

Ukulingisa ukufa

Yini i-die-cast?

Ukukhipha ingcindezi kubizwa nge-die casting

Indlela ye-die-casting lapho uketshezi oluncibilikisiwe lwe-alloy luthelwa ekamelweni lokucindezela,

i-cavity yesikhunta sensimbi igcwaliswa ngesivinini esikhulu, futhi uketshezi lwe-alloy luqiniswa ngaphansi kwengcindezi yokwenza ukukhishwa.

Inzuzo kanye nokubi kwe-die casting:

Inzuzo: ikhwalithi enhle yokukhiqiza ephezulu intengo enhle

Ububi: izinto ezilinganiselwe kuphela i-aluminium zinc magnesium lead tin yethusi ingasetshenziselwa ukusakaza kuze kube manje.

Imishini ebizayo, kanye namathuluzi abiza kakhulu

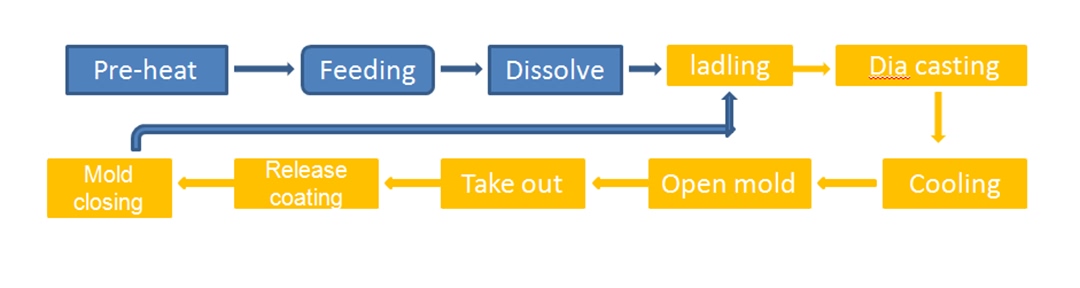

Ingxoxo yokugeleza okufayo:

Ukwelashwa kwezingxenye ze-Die casting surface:

1.Ukudweba

2.Powder enamathela

3.Plating

4.I-oxide anodizing

5.Ukupholisha, ukugcoba

6.Ukudweba kwamafutha

7.Ukuqhunyiswa kobuhlalu

Iphutha elikhulu lokulingisa ifa

Ngaphakathi: I-Stomata, imbobo yokushwabana, imbobo yesihlabathi, okuxekethile

Ubuso: Ukuqhekeka, ukwahlukanisa okubandayo, uhlobo olungalungile, i-billet enkulu, ibhamuza, idiphozithi yekhabhoni,

isikhunta esinamathelayo, uhlobo, sag, trace, pockmark, scouring, crack, isigubhu esiphezulu, ukubhoboza

I-Die-casting ingenye yezindlela eziphambili kakhulu zokwakha insimbi.Ngokuthuthuka okuqhubekayo kobuchwepheshe be-die-casting,

ama-alloys e-die-casting awasagcini ezinsimbi ezingenayo insimbi njenge-zinc, i-aluminium, i-magnesium nethusi.Ubukhulu nesisindo sokufa-

izingxenye zokuphonswa zizokwanda njengoba amandla omshini wokukhipha i-die-cast ekhula, ngakho-ke ithemba le-die-casting libanzi kakhulu.

Inqubo yokulingisa i-Die Castiority nayo inemikhawulo yayo.Ikhwalithi, ikhwalithi kanye nezindleko zemikhiqizo

kusetshenzwe izinqubo ezahlukene zihlukile.Indlela yokukhetha ukucubungula komkhiqizo okulungile

inqubo kunqubo yokukhiqiza idinga ukuthi sikhethe.

Ukulingisa ukufa

Yini i-die-cast?

Ukukhipha ingcindezi kubizwa nge-die casting

Indlela ye-die-casting lapho uketshezi oluncibilikisiwe lwe-alloy luthelwa ekamelweni lokucindezela,

i-cavity yesikhunta sensimbi igcwaliswa ngesivinini esikhulu, futhi uketshezi lwe-alloy luqiniswa ngaphansi kwengcindezi yokwenza ukukhishwa.

Inzuzo kanye nokubi kwe-die casting:

Inzuzo: ikhwalithi enhle yokukhiqiza ephezulu intengo enhle

Ububi: izinto ezilinganiselwe kuphela i-aluminium zinc magnesium lead tin yethusi ingasetshenziselwa ukusakaza kuze kube manje.

Imishini ebizayo, kanye namathuluzi abiza kakhulu

Ingxoxo yokugeleza okufayo:

Ukwelashwa kwezingxenye ze-Die casting surface:

1.Ukudweba

2.Powder enamathela

3.Plating

4.I-oxide anodizing

5.Ukupholisha, ukugcoba

6.Ukudweba kwamafutha

7.Ukuqhunyiswa kobuhlalu

Iphutha elikhulu lokulingisa ifa

Ngaphakathi: I-Stomata, imbobo yokushwabana, imbobo yesihlabathi, okuxekethile

Ubuso: Ukuqhekeka, ukwahlukanisa okubandayo, uhlobo olungalungile, i-billet enkulu, ibhamuza, idiphozithi yekhabhoni,

isikhunta esinamathelayo, uhlobo, sag, trace, pockmark, scouring, crack, isigubhu esiphezulu, ukubhoboza

I-Die-casting ingenye yezindlela eziphambili kakhulu zokwakha insimbi.Ngokuthuthuka okuqhubekayo kobuchwepheshe be-die-casting,

ama-alloys e-die-casting awasagcini ezinsimbi ezingenayo insimbi njenge-zinc, i-aluminium, i-magnesium nethusi.Ubukhulu nesisindo sokufa-

izingxenye zokuphonswa zizokwanda njengoba amandla omshini wokukhipha i-die-cast ekhula, ngakho-ke ithemba le-die-casting libanzi kakhulu.

Inqubo yokulingisa i-Die Castiority nayo inemikhawulo yayo.Ikhwalithi, ikhwalithi kanye nezindleko zemikhiqizo

kusetshenzwe izinqubo ezahlukene zihlukile.Indlela yokukhetha ukucubungula komkhiqizo okulungile

inqubo kunqubo yokukhiqiza idinga ukuthi sikhethe.